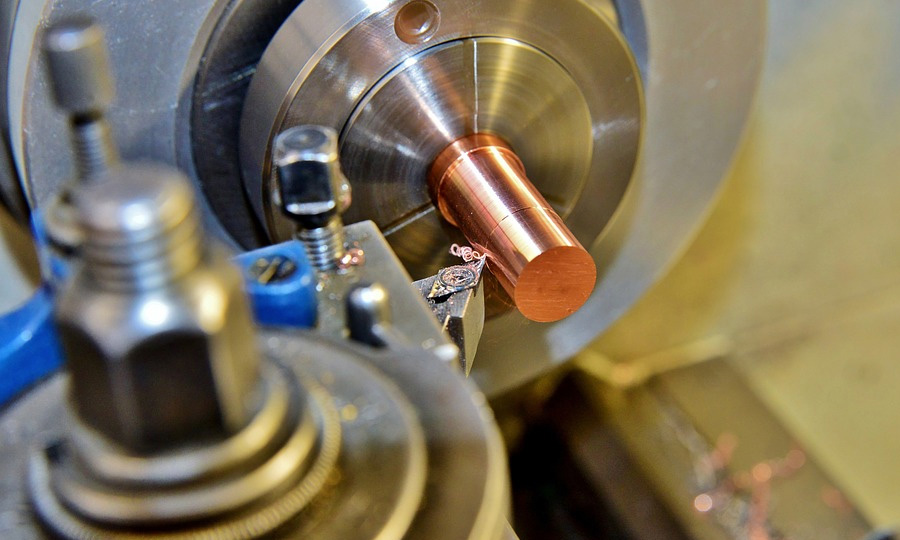

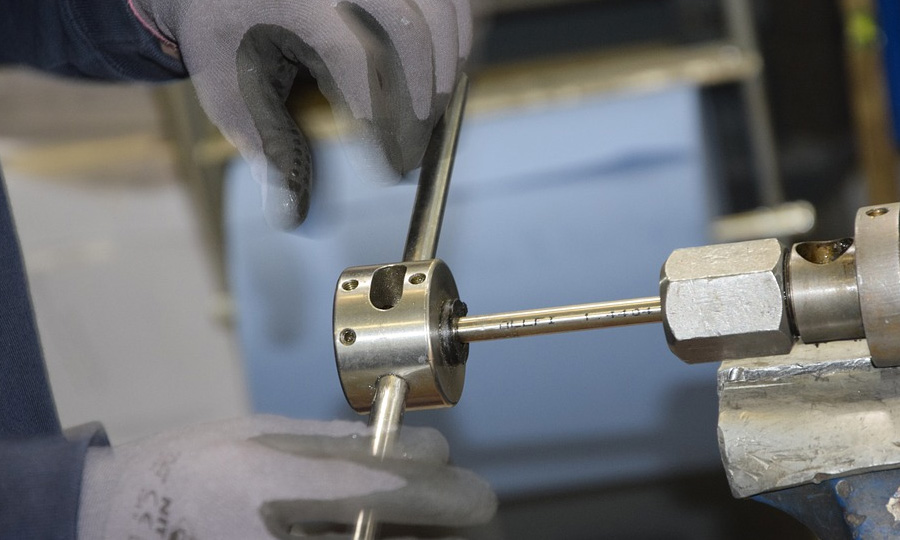

The hot melt laminating machine plays an important role in coating and laminating. Similar to a tape coater, it is also very helpful for people's production. In the production and operation process, the operation of the hot melt adhesive laminating machine and the belt coating machine is not very complicated. You should also pay attention to cleaning the machine. Damage to the machine is very important. It is easily damaged by dust.

An important feature of the intelligent control system of the hot melt compound machine is the automatic monitoring and fault diagnosis of each component. For example, external faults are usually caused by power, pollution, and collisions. Failures are usually caused by wear, lack of lubrication, or failure of actuators and sensors. If the fault directly affects the measurable output variable, the fault can be detected by proper signal evaluation, and the tolerance between the measured value and the normal value can be compared. If it is greater than the tolerance, an alarm will be triggered. The corresponding function is called monitoring. When it is greater than the range value indicating the dangerous state, the corresponding operation will run automatically, which is called automatic protection.